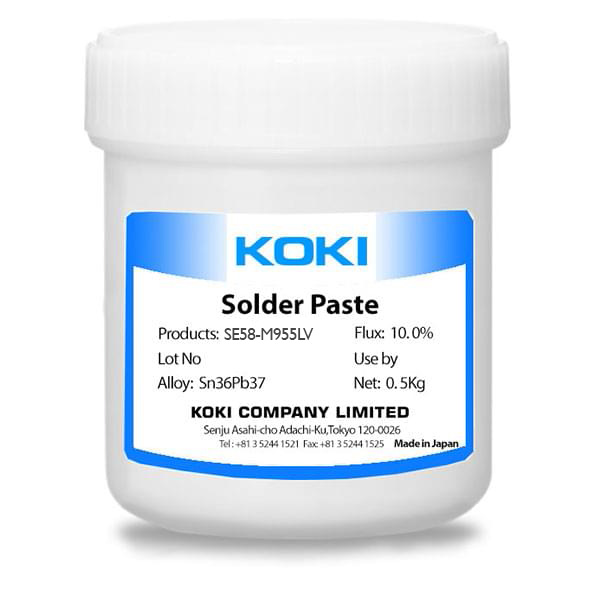

KOKI SE58 Solder Paste | SE58-M955LV Leaded

Koki no-clean Leaded solder paste

KOKI Leaded Blue Paste

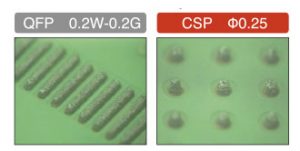

KOKI SE58-M955LV Outstanding continual and intermittent print-ability even with fine pitch pattern (0.4mm pitch, o.25mm∅) applications

Superior workability, solderability and electrical reliability.

Applicable for super fine pitch SMT production.

KOKI SE58 Solder Paste

Employment of rigidly classified 20-38 micron solder powder ensures outstanding continual printing with fine pitch (0.5mm/20mil) and even super fine pitch (0.4mm/16mil) application and long stencil idle time.

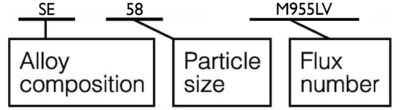

Specifications – Alloy selections

Performance of SE58-M955LV

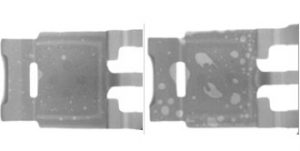

Printability

Sharp print definition

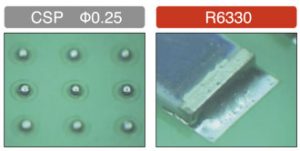

Wettability

Excellent wetting

Voiding property (PwTr)

SE58-M955LV Conventional

Solder alloy composition is Sn37Pb

- Employment of rigidly classified 20-38 micron solder powder ensures outstanding continual printing with fine pitch (0.5mm/20mil) and even super fine pitch (0.4mm/16mil) application and long stencil idle time.

- Carefully selected flux chemistry ensures low voids formation.

- Extremely long stencil idle time and tack time offers a wide process window

- Low color flux residue offers superior cosmetic appearance.

- Conforms to Bellcore tests (Copper Mirror, Halides, Surface Insulation Resistance, Electro migration) GR-78-CORE, Issue 1.

- Uses carefully classified solder powder with uniform particle size.

- Superior workability, solderability and electrical reliability.

- Applicable for super fine pitch SMT production.

| Application | Printing – Stencil | |

| Product | SE-58-M955LV | |

| Alloy | Composition (%) | Sn63, Pb37 |

| Melting point (°C) | 183 | |

| Shape | Spherical | |

| Particle size (μm) | 20 – 38 | |

| Flux | Halide content (%) | 0.0 |

| Flux type | ROL0 | |

| Product | Flux content (%) | 10 ± 0.5 |

| Viscosity*1 (Pa.S) | 200 ± 10% | |

| Copper plate corrosion*2 | Passed | |

| Tack time | > 48 hours | |

| Shelf life (below 10°C) | 6 months | |

Reviews

There are no reviews yet.