KOKI S3X58-M500C-5 | Lead Free Solder Paste

- KOKI S3X58-M500C-5 Powerful Wetting General Purpose Solder Paste

- Powerful Wetting Lead Free Solder Paste

- Koki no-clean LEAD FREE solder paste

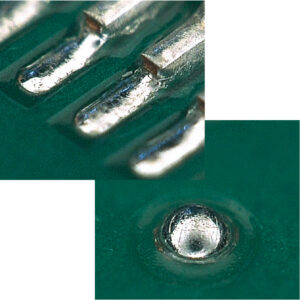

Good and Consistent Wetting Spreading to Oxidized Metal Surface

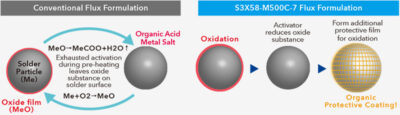

Activator Technique

After removal of oxide film at pre-heating stage, a new protective film formed on the surface of solder particles to effectively prevent re-oxidation during the remaining heating process thereby results in powerful wetting/melting.

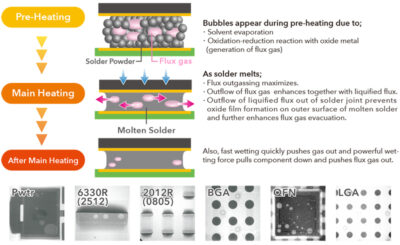

Low Voiding Technique

Solder Spreading Property

After continual print, pause 45 min. or 60 min. and resume printing and observe print volume.

Test condition

Stencil : 200μm / 6.5mmφ aperture

Pre-conditioning : 150ºC for 16Hr

Heat source : Convection reflow

Reflow : Air

Solder alloy composition is Sn 3.0Ag 0.5Cu

- EXCELLENT WETTING to severely oxidized patterns or components, such as oxidized Cu substrate, oxidized Sn and NiPd plating.

- PERFECT MELTING and wetting at super fine pitch (>0.4mm pitch) and micro components (>0.25mm dia CSP, 0603 chip).

- Specially formulated flux chemistry ensures EXTREMELY LOW VOIDING with CSPs and broad contact area components, e.g. QFN.

- Designed to prevent occurrence of HIDDEN PILLOW DEFECTS.

- Enables REUSE of leftover from previous day. Economical.

| Application | Printing – Stencil | |

| Product | S3X58-M500 | |

| Alloy | Alloy Composition (%) | Sn 3.0Ag 0.5Cu |

| Melting point (°C) | 217 – 219 | |

| Shape | Spherical | |

| Particle size (μm) | 20 – 38 | |

| Flux | Halide content (%) | 0 |

| Flux type | ROL0 | |

| Product | Flux content (%) | 11.5±1.0 |

| Viscosity (Pa.S) | 220±30 | |

| Copper plate corrosion*2 | Passed | |

| Tack time | > 48 hours | |

| Shelf Life (0-10ºC) | 6 months | |

| Optional powder size (µm) | 20 – 45; Product code S3X48-M500 | |

Reviews

There are no reviews yet.