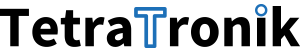

Automatic Wave Soldering Machine

JT Series of Wave Soldering Machine – Automatic Wave Soldering Machine

- New solution of preheating: The hot air preheating u- shaped heater has a long service life, and reduces maintenance downtime. Internal reinforcement insulation plus an optional external protection device can effectively reduce the heat loss, energy-saving up to 20% compared with traditional equipment. Lower body temperature with better work environment.

- External Spray Fluxer, safety, cost, space, and maintenance problems resolved: External and independent spray control system, ensure the safety and clean, easy to operate and maintenance; Transportation of new type titanium alloy heavy-duty claw, sectional guide rail design, stainless steel strip supported in guide rail, long life; The solder pot adopts special materials, Anti corrosion coating on surface; Adopt imported precision nozzle, atomization uniformity, highly efficient.

- The large promotion of solder pot:Automatic Wave Soldering Machine Nozzle quick released, reduce maintenance time, 2 hours to a few minutes; Grid type of mesh, reduce the mesh block by solder dross monthly maintenance extended to six months; Optional auto solder supplying device, reduce the influence of wave height caused by a drop of solder level;

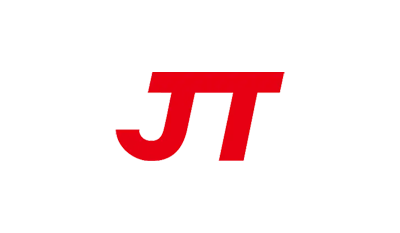

| Model NO | 350 Series | 450 Series | 610 Series | ||||||||||||||

| SMART-350-V2-M | SMART-350-V2-H | SMART-450-V2-M | SMART-450-V2-H | SMART-610-V2-H | |||||||||||||

| Dimensions (L*W*H) MM | 3945*1582*1735 | 4445*1582*1735 | 3945*1582*1735 | 4445*1582*1735 | 4445*1742*1735 | ||||||||||||

| Spray Fluver Dimensions | 1300*1350*1595 | 1400*1510*1595 | |||||||||||||||

| Power Supply | AC 380V 3Φ5W 50/60Hz ( Option: AC 220V3P 50/60Hz) | ||||||||||||||||

| Initial/ Operating Power | 8KW | 8.5KW | 9KW | 9.5KW | 11.5KW | ||||||||||||

| Starting Power | 37KW | 43KW | 37KW | 43KW | 64KW | ||||||||||||

| Air Sourse | 0.5-0.8Mpa | ||||||||||||||||

| Control System | PC +PLC | ||||||||||||||||

| Flux Flow | 10~100ml/min | ||||||||||||||||

| Exhaust Tube Diameter | 200mm | ||||||||||||||||

| Exhaust Mode | Upward | ||||||||||||||||

| Preheat Mode | IR/Hot Air | ||||||||||||||||

| Preheat Zone Number | 3 zones/1800mm | 4 zones/2280mm | 3 zones/1800mm | 4zones/2280mm | 4 zones/2280mm | ||||||||||||

| Preheat Temp Range | Room Temp ~ 280 ℃ | ||||||||||||||||

| Temp Control Mode | PID+SSR | ||||||||||||||||

| Solder Pot Type | Mechanical Pump | ||||||||||||||||

| Pot Capacity | Approx. 480 kg | Approx. 550 kg | Approx. 800 kg | ||||||||||||||

| Max. Soldering Temp | Max : 300 ℃ | ||||||||||||||||

| Wave Driving Power | 1/4 HP X2 | ½ HP X2 | ½ HP X1 1HP X1 | ||||||||||||||

| Wave Height Control | Inverter | ||||||||||||||||

| Heat Up Time | Approx 110min (250 ℃) | Approx 120min (250 C) | |||||||||||||||

| PCB Conveying Speed | 300 ~ 1800 mm/min | ||||||||||||||||

| The Width of PCB | 50-350mm | 50-450mm | 50-610mm | ||||||||||||||

| Component Height | Top : 120mm Bottom 25mm | ||||||||||||||||

| Transport Height | 750±20mm (Entrance) | ||||||||||||||||

| Conveyor Angel | 4 7 Adjustable | ||||||||||||||||

| Speed Control Mode | Inverter | ||||||||||||||||

| Cooling Method | Forced Air Cooling (Option : Chiller) | ||||||||||||||||

| N2 System | SMART-350-V2-M-N | SMART-350-V2-H-N | SMART-450-V2-M-N | SMART-450-V2-H-N | SMART-610-V2-H-N | ||||||||||||

| Nitrogen Consumption | 15m/h 1000ppm | ||||||||||||||||

| Pressure Nitrogen Source | 0.5-0.8Mpa | ||||||||||||||||

| Oxygen Nitrogen Source | ≤10PPM | ||||||||||||||||

| Oxygen Analyzer | Option | ||||||||||||||||

Reviews

There are no reviews yet.