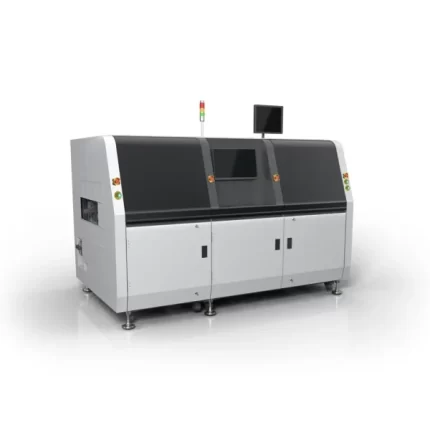

JT Dalgalı Lehimleme Makinekeri

| Model NO | NXS-450 | |

| Parameters | Dimension(LxWxH) | 5635x1620x1735mm |

| Supply Power (3 phases 5 wires) | 3P5W380V AC,50/60Hz 160A or 3P5W220V AC,50/60Hz 130A | |

| Required Lnitial Power | 90KW | |

| Required Air Source Power | 0.5~0.8Mpa | |

| Total Power | 60KW | |

| Operating Power | 10-13KW | |

| Control Method | PC+PLC | |

| Air Sourse | 0.5-0.8Mpa | |

| Control System | PC +PLC | |

| Spray System | Flux Flow | 10~100ml/min |

| Spray Pressure | 0.25MPa-0.4MPa | |

| Preheating System | Preheating Method | Hot air/IR for option(module) |

| Speed Adjustment Mode | IR: Ni | |

| Quantity | 3 sections (4 sections for option) | |

| Length | 1950mm (3 segments); 2250mm (4 sections) | |

| Temp. Range | Room temperature – 280 ℃ | |

| Temp. Control Mode | PID+SSR | |

| Soldering System | Wave Peak Operation Mode | Mechanical pump |

| Power for Heating Tube | 1.5KW*12 | |

| Pot Capacity | Approx 550KG | |

| Ultimate Bearing Temperature | Max: 300 ℃ | |

| Ultimate Usage Temperature | Max: 280 ℃ | |

| Wave Peak Driven Power | 1/2 HPx2 AC 220V3Φ | |

| Height Adjustment Mode | Inverter adjustment | |

| Heating Time | 100 min 250℃ | |

| Wave Peak Select | Dual-wave: Spoiler + flat or Spoiler + Spoiler | |

| Wave Height | 0~15mm | |

| PCB Conveyor System | Conveying Speed | 0~1800mm/ min |

| Width Range of PCB | 50-450mm | |

| Length Range of PCB | 120-600mm | |

| Height of PCB Component | Top: 150mm Bottom: 25mm | |

| Conveyor Height | 750±20mm | |

| Angle of Rail | 5.5 fixed | |

| Motor Rotation Mode | Sectional transimmission/control | |

| Conveyor Motor Powe | 90W*3 3P 220V AC | |

| 40KG | ||

| Conveyor Mode | fragment conveyor: chain- fingers (V+L/full V/ full L) – chaiN | |

| Conveyor Motor Speed Adjustment | Inverter adjustment | |

| Gas Parameters | 30m³/h 1000ppm | |

| Nitrogen Source Pressure | 0.5-0.8MPa | |

| Nitrogen Source Oxygen Content | ≤10PPM | |

| No.of Nitrogen Flowmeter | 7 | |

| Others | Exhaust Fan | AC380V 750W |

| Diameter of Exhaust Duct | Φ200mm | |

Değerlendirmeler

Henüz değerlendirme yapılmadı.