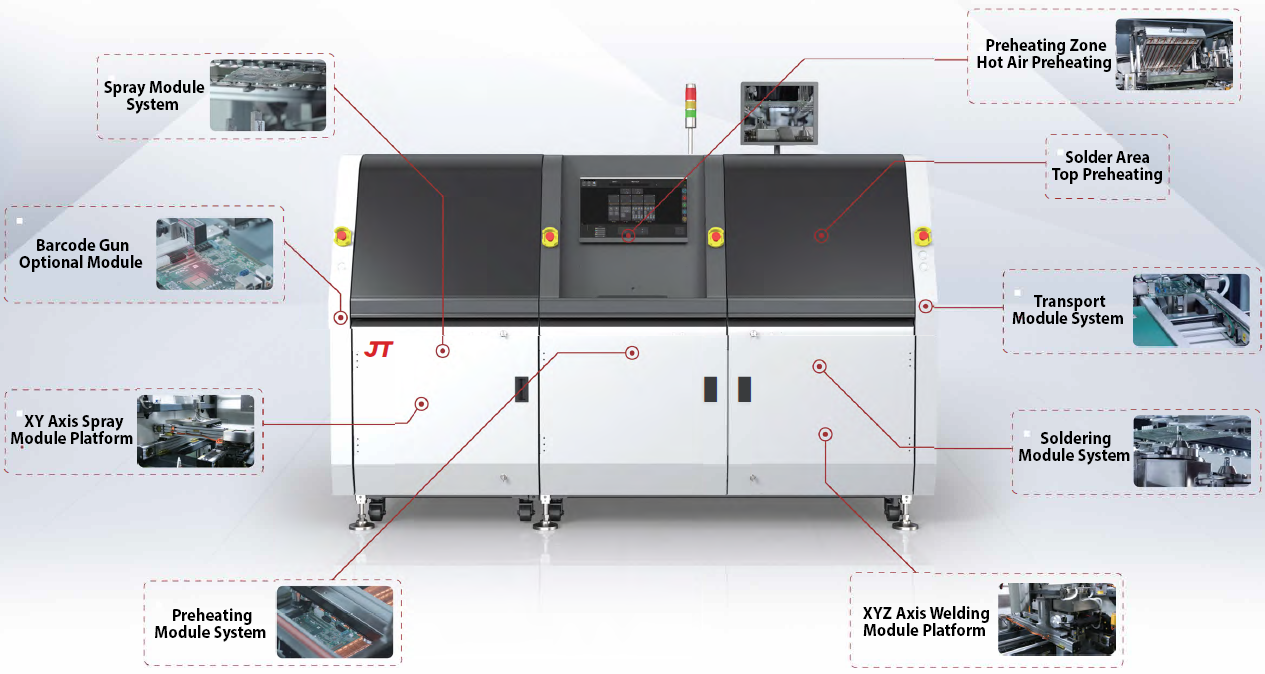

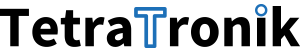

NIS-450 Selective Soldering

JT NIS-450 Selective Soldering Machine

- Selective wave soldering meets the current demand for high standard welding performance, reflecting the flexibility and scalability of the welding process.

- The third generation JT on line selective wave soldering, with new innovative features suitable for future needs.

- Modular systems have multiple configuration possibilities and can ideally be customized to meet various needs.

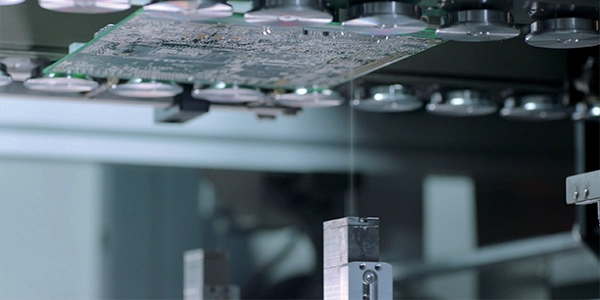

Two independent spray modules can be configured for selective wave soldering in rosin spray module, It can meet the application of product spray time and rosin type. Precise spray flux system with spray test function and flow level monitoring.

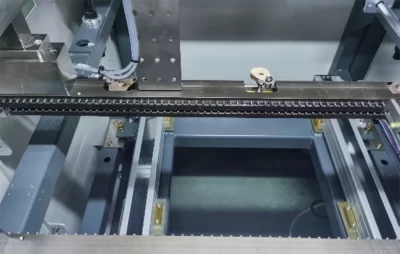

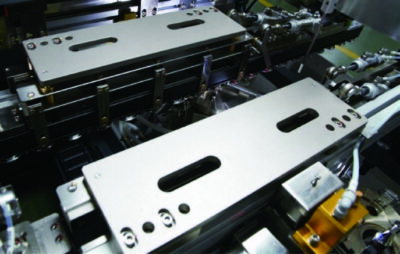

Transport Module System

- The selective wave soldering transportation system is equipped with chain and roller type transmission and full turntable transportation, with segmented control transportation system.

- The unified width adjustment control system can be better applied to the application of bare plates and fixtures.

- The track width is automatically controlled by software, which can meet the maximum production requirements of various sizes of PCB boards of 700 x 610mm.

- A dual track transportation system can be selected to meet the requirements of welding bare plates simultaneously.

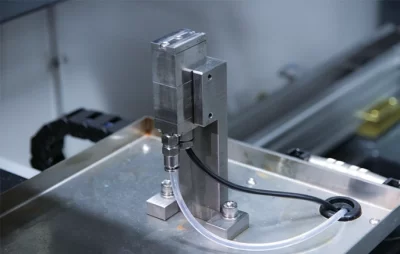

Spray Module System

XY axis servo motor drive control system.

Spray width: 2~8 mm (diameter 130 µ M nozzle).

Excellent PCB board cleanliness after welding.

Save over 95% of welding flux.

Accurate flux usage.

Programmable point spray and line spray.

Option: rosin blockage detection.

Related hardware

Chain transportation

Roller transportation

XYZ clamping

High precision pulse spray system

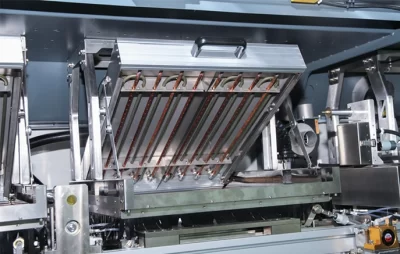

Preheating Module System

The preheating module is mainly equipped with top hot air and bottom infrared heater, For PTH complex process PCB, power heating mode is also configured, To ensure efficient, safe and uniform heating effect.

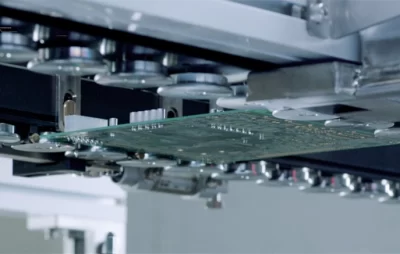

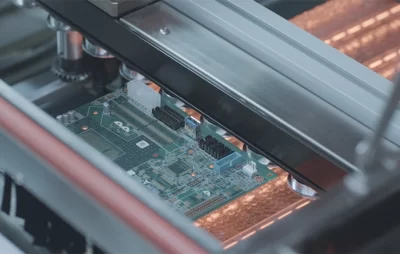

Double-cylinder independent electromagnetic pump selective crest

Electromagnetic drive control peak system, stable peak state.

X/Y/Z 3-axis servo control system, reliable positioning accuracy.

Customized solder tips to meet the customized needs and process standards of different customers.

Nitrogen protection ensures durable and reliable welding.

Welding Module System

The welding module is driven by an electromagnetic pump, Selective wave soldering can be configured with upto3welding modules, each module is equipped with dual tin cylinders corresponding to larger production capacity requirements.

Related hardware

Bottom infrared preheating

Top hot air convection preheating

Automatic cleaning nozzle (option)

Automatic crest correction (standard)

Automatic wire feeder (option)

JT NIS-450 Selective Soldering

- Spray Fluxer + Preheating + Soldering module, integrated design, flexible configuration and free expansion.

- The point soldering module and the group soldering module are freely matched and combined.

- The most efficient selective soldering module.

- Sectional modular transmission structure.

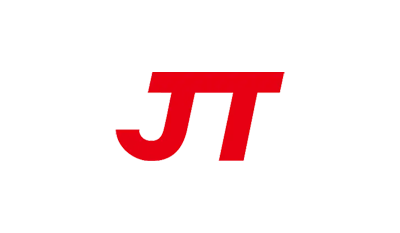

| Model | NIS-450 |

| Parameters | |

| Dimension L×W×H | 2600×1800×1650mm(1-2 pot) |

| Transporting System | |

| PCB Width | 60-450mm |

| PCB Length | 120-500mm |

| PCB Top Space | Max :120mm |

| PCB Bottom Space | Max :50mm |

| PCB Edge Size | 4mm |

| Conveyor Height | 900±20 |

| Conveying Speed | 0.2-10m/min |

| PCB Weight | Max:5kg |

| Fluxer Module | |

| Flux Capacity | 2L |

| The Size of Flux Nozzle Tube | 130um |

| Flux Width | 2-8mm |

| Preheating Module | |

| Bottom movable Infrared Heater | Max:14kw |

| Temperature Range | Room Temperature-250℃ |

| Top Air Heater | Max:6kw |

| Soldering Module | |

| Min Diameter of Solder Nozzle | ¢2/4.5 |

| Wave Height | 3〜5mm |

| Solder Pot Capacity | 8KG(Solenoid Pump)/13KG(Mechanical Pump) |

| Soldering Temperature | Max:350℃ |

| Heating Time | 40min/ (Mechanical Pump 300℃)/75min/ (Solenoid Pump 300℃) |

| Pot Heating Power | 1KW/ Single pot |

| Location Speed | X/Y:2-200mm/s |

| Temp. Control Accuraey | ±2℃ |

| Soldering Accuracy | ±0.25mm |

| Control System | |

| PC Operating System | Windows 10 |

| Process Visualization | CCD Visual |

| Software Language | Chinese and English Changeable |

| Programming Mode | Inline/Off line Programming |

| Data Import | Gerber, Image Introduction |

| Air System | |

| Air Supply | N2/O2 |

| Required Pressure | 0.4-0.8Mpa |

| N2 Consumption | Each consumes about 1.5-2 m³/h |

| N2 Concentration | ≥99.999% |

| Electrical Parameter | |

| Power Supply | AC 380VAC 3Φ5W 50/60Hz |

| Consumption | 35KW |

| Air Exhaust | |

| Air Duct Diameter | ¢200mm x3 |

| Exhaust Air Rate | 360 m³/h |

Reviews

There are no reviews yet.