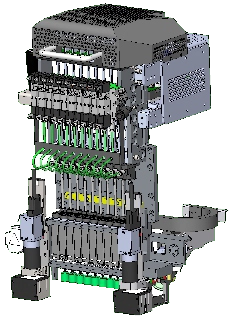

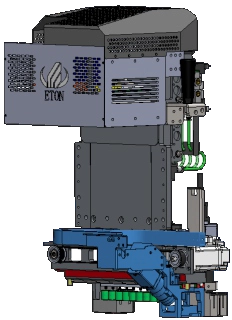

YT10S Pick and Place Machine

High-speed multi integrated machine ,Breaking Through industry conventions, Greatly improving mounting speed accuracy stability.

YT10S Pick and Place Led Light Smt Mounting Machine For Led Bulbs

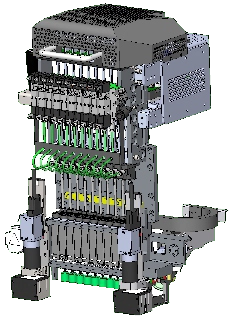

1.Single module mantic linear motor multifunctional pick and place machine

2.Mounting components: LED, capacitors, resistors, IC, shaped components, etc.

3.Application: power driver, electric board, lens, linear bulb, household appliance etc.

4.Component:min.size 0402 max, height 36 mm.

International Invention Patent:Placement Head

YT10S Pick and Place Machine

Integrated Placement Head

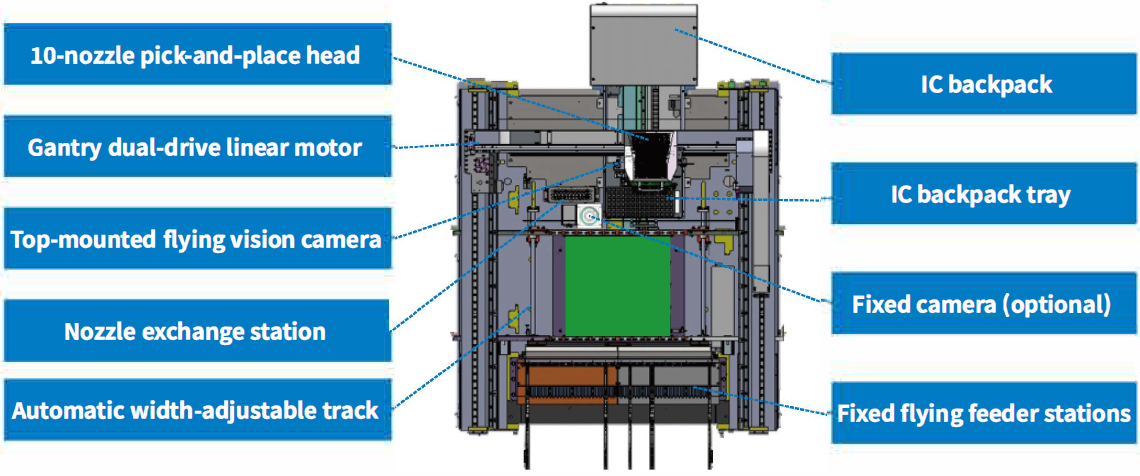

Lightweight an integrated head design, and 10 sets of Z axes independently controlled by modular magnetic liner motors, resulting in significant improvements speed, accuracy, and stability.

Precise Corner System

The modular corner system independently controls the angle of each components to ensure high-precision placement there are 10 suction nozzles per head, with a center distance of 16mm.

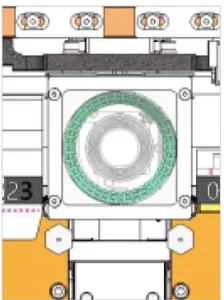

Vision System

The integrated high-speed and precise flying recognition camera enhances recognition, recognize during X and Y axis movement to once again improve placement efficiency

Ultra-High-Speed Capability

Adopting high-end magnetic liner motors and a multi-function modular head, the placement capability has increased 25% compared to traditional machines, with an optimum placement speed reaching 48,000CPH.

Vacuum Sensing Device

Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product.

Feeder Cart (Optional)

One Feeder Cart accommodates 23 PCS feeder station, equipped with optional automatic tape cutting function. Depending on the product requirements, the feeder cart and IC cabinet can be switched with a one-touch changeover method to minimize changeover time.

Intelligent Electric Feeder

Support YT Series double head intelligent electric tape reel feeder, by optically correcting the feeding position of the component, it can achieve stable, accurate high-speed feeding.

IC Backpack

Supports 15-layer trays, with the ability to switch freely.

Features

High Reliability Stable Production

- YT10S Pick and Place Brand new self-developed high-precision placement head.

- Combining a high-accuracy mark recognition camera with a fixed-flight vision camera to ensure placement accuracy.

- The placement head adopt independent vacuum detection, improve placement accuracy.

- Off-line programming, saves time during short changeover cycles.

- The software includes learning and automatic optimization function.

- YT10S Pick and Place Provides/Supports MES system interface.

- Equipped with coordinate import function.

- Optional IC backpack, flexible production

- Flexible line is achievable through modular placement heads and various production.

- Single gantry, 10 spindles

- Maximum PCB board: 500*450mm, minimum 50*50mm.

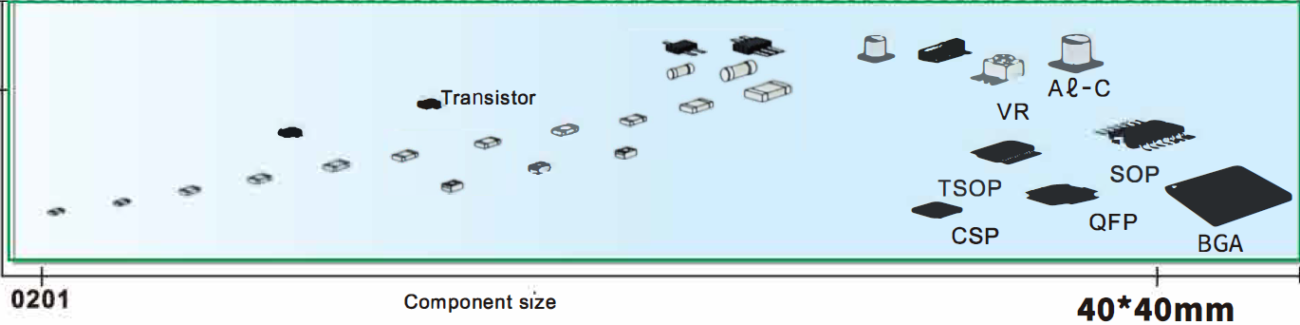

Component Size

For Small Components Only, Can Set Mounting Height at 10mm to Improve Mounting Capacity

YT10S Pick and Place Optical Recognition Camera

High Flight recognition + fixed flight recognition (optional), components with size less than 40*40mm and height less than 16mm can ne used to High-speed and high-precision identification.

Double Mark Camera Recognition

High-precision mark recognition system, adopt 3-color illumination recognition, apply to any shape mark, wider range of applications.

Fixed Flight Vision Camera (optional)

High-speed flight vision camera, quickly captures multiple head images at once, perform visual calibration, adjustable light source brightness.

YT10S Pick and Place Machine | 48000CPH

- X, Y, Z axis all adopt self-developed-end magnetic linear motor Y axis adopts double drive gantry structure.

- The worlds first use of single-phase 220V power supply, low energy consummation.

- Support automatic nozzle change function (option).

- Support IC backpack & IC tray function (option).

- Each head is independently controlled by separately driver, each nozzle can independently test CPK.

- Apply to 0201~15*15mm tape reel package and IC tray feeder (15*15~40*40mm components need to option fixed camera)

| Model | YT10S |

| PCB Size | Max:500*450mm

Min:50*50mm |

| PCB Thickness | 0.5-5mm |

| PCB Clamping | Cylinder clamping, track width adjustable |

| Fixed rail way | Rail 1 is fixed rail |

| System | Windows 7 |

| Software | R&D independently |

| Off-line programming | Available |

| No. of head fly vision camera | 1 PCS |

| 2 PCS | |

| Calibration method | Vision alignment + mark correction |

| Repeat precision | Chip ± 0.03mm QFP± 0.025mm Cpk˃1.33(3ϭ) |

| Display | LED monitor |

| No. of Camera | 1 PCS (Head flight vision camera) |

| 2 PCS Mark camera | |

| Mounting Precision | CHIP±0.03mm QFP±0.025mm Cpk≧1.0 (3σ) |

| Mounting Component Height | Standard: ≦16mm Special Setting: ≦10mm |

| Mounting Speed | 48000 CPH |

| Components Range | 0201~15*15MM packaging material and IC material (Optional fixed camera for 0201~40*40MM |

| Power | 1ϴ 220AC 50HZ |

| Operating Environment | 23℃ ±3℃ |

| Transmission Direction | Standard: Single Direction |

| Transmission Mode | Online drive |

| Position Mode | Optical |

| Air consumption | 0.4-0.6 mpa (4-6kgf/cm²) 100L/min |

| Transmission Speed | >1000mm/sec |

| Electrical control | Independent research and development by ETON |

| Motion control card module 1 set | Independent research and development by ETON |

| X,Y,Z Axis Drive way |

High-end magnetic linear motor |

| No. of Feeder station | 52 PCS |

| No. of Heads | 10 PCS |

| Feeding way | Electric Feeder |

| MES System interface | Customized |

| Fixed fly vision Camera | Option |

| IC Pack | Option |

| 17-Station feeder cart | Option (equipped whit IC pack) |

| 52-Station feeder cart | Option |

| 23-Station feeder cart | Option |

| Cutter | Option |

| Mobile IC Cabinet | Option (equipped whit IC pack) |

| Nozzle exchange station | Option |

Reviews

There are no reviews yet.